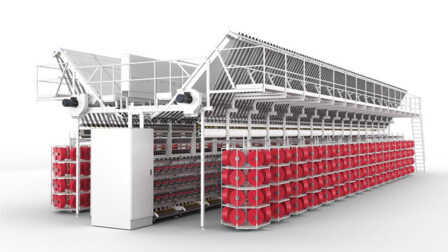

With the new eFK EvoSmart machine generation, we are setting new standards for highly efficient texturing processes. Intelligent technologies and energy-efficient components offer you multiple benefits.

25% less energy consumption per kilogram of yarn thanks to:

- Innovative EvoHeater heating technology and optimized processes

- Single-converter-controlled, energy-efficient Smart Godets

- IE5 motor technology that already meets future efficiency and performance requirements today

- Reduced heat dissipation for lower cooling requirements for the building

50% less maintenance thanks to:

- New EvoHeater heating technology with significantly reduced contamination

- Doubled maintenance intervals with consistent performance

- Faster and easier cleaning, saving both time and personnel resources and eliminating the need for chemical cleaning agents

Your advantage: Up to 15% lower conversion costs

The combination of energy savings and reduced maintenance costs lowers your operating costs in the long term – and increases your competitiveness. You benefit from

- higher margins

- more production time

- future-proof technology